The hot-pressed composite boron nitride ceramic products produced by Zhuoyu Technology adopt the international high-quality vacuum hot-pressing sintering process, with the industry's high-quality technical support and unique material ratio, to ensure that the material has good thermal conductivity, high thermal shock resistance, erosion resistance and other properties, suitable for a series of high-performance industrial applications.

Product advantages:

① High thermal conductivity, pressed into various forms, used as high temperature, high pressure, insulation, heat dissipation components, such as aircraft, rocket engine nozzles.

Excellent thermal shock resistance, erosion resistance, applied to amorphous ribbon and amorphous nozzle, three D printing metal powder guide tube, nozzle and other high strength non-adhesion, applied to a variety of hot pressing mold.

Product Application:

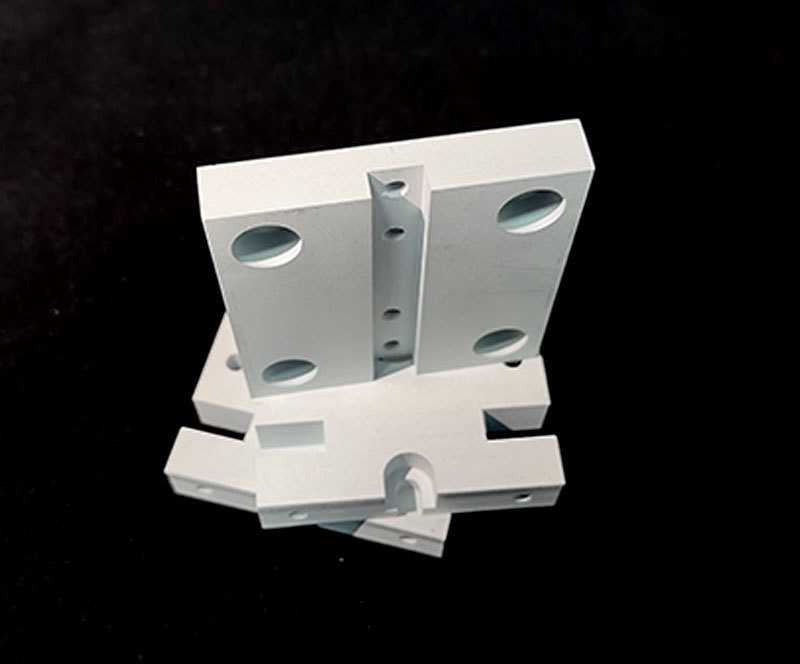

● Boron nitride horizontal continuous casting separation ring;

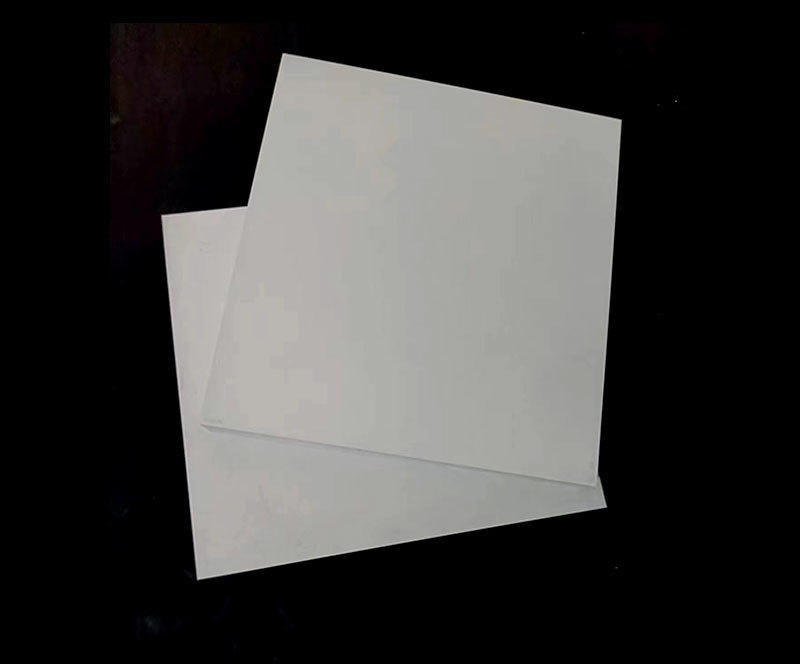

● Boron nitride thin strip continuous casting side sealing plate;

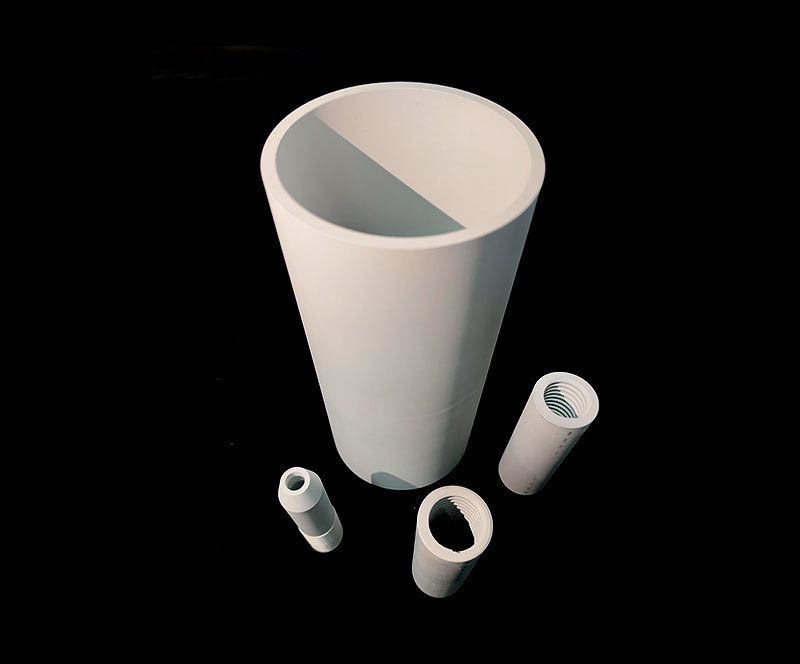

● amorphous, nanocrystalline with boron nitride nozzle;

Special metal powder nozzle and guide pipe;

Zhuo Yu can be customized according to customer drawings and requirements of a variety of heterosexual composite boron nitride products.

|

Category |

Composite boron nitride ceramics |

|

|---|---|---|

|

Main components |

|

BN+Zr02+SiC |

|

Density |

g/cm³ |

2.3 |

|

Dietmar Leeb |

HL |

500 |

|

Bending strength |

Mpa |

150 |

|

Thermal expansion coefficient(25℃-1200℃) |

(10-6/K) |

2-3 |

|

Thermal conductivity (At room temperature) |

W/mk |

15 |

|

Maximum operating temperature |

Air |

900℃ |

|

Vacuum |

1500℃ |

|

|

Inert atmosphere |

1700℃ |

|

|

Room temperature resistivity |

Ω.cm |

>1012 |