Zhuoyu nitrogen adopts the international high-quality vacuum hot pressing sintering process to produce hexagonal boron nitride ceramic products, which have good electrical insulation, thermal conductivity and chemical stability. No obvious melting point, the use temperature in inert gas can reach 2300 ℃, and the stability in oxygen atmosphere is poor, which can be used to 900C. Hexagonal boron nitride has a coefficient of expansion equivalent to quartz but a thermal conductivity ten times that of quartz.

Product advantages:

① It has good heat resistance, thermal stability, thermal conductivity and high temperature dielectric strength, which is an ideal application for heat dissipation and high temperature insulation environment.

②It has good chemical stability, can resist the erosion of most molten metals, and has excellent self-lubricating properties.

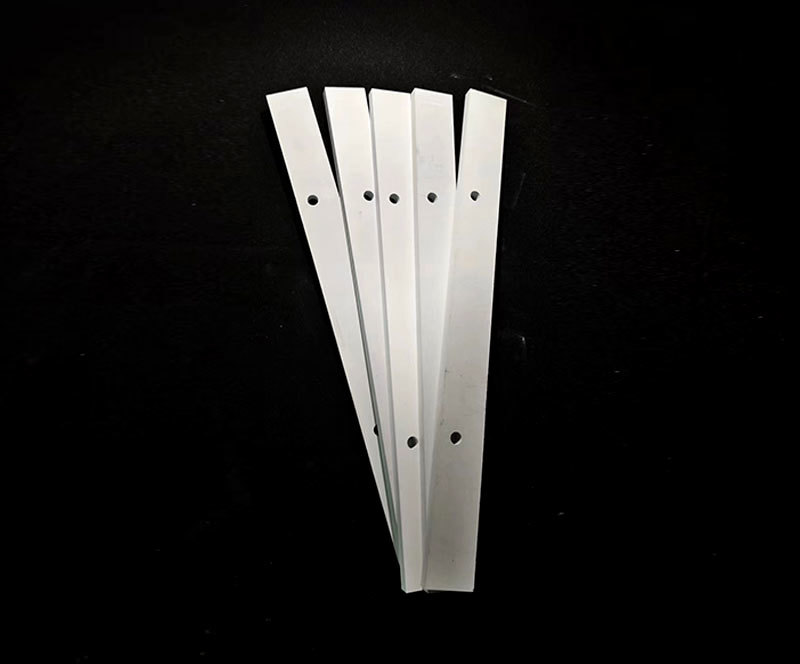

③ easy machining, can be processed according to the need to get the required shape and size

Product Application:

● Crucibles for melting semiconductors:

● Semiconductor heat dissipation and insulation parts;

● High temperature bearings, valve gaskets, etc.

● Amorphous ribbon nozzle and powder metal atomizing nozzle

● Hot sleeve: horizontal continuous casting separation ring

● Glass forming dies.

Zhuo Yu can be customized according to customer drawings and requirements of a variety of heterosexual boron nitride products.

|

Category |

High purity boron nitride ceramics |

|

|---|---|---|

|

Main components |

BN |

99.6% |

|

Density |

g/cm³ |

>2.0 |

|

Oxygen content |

|

0.4664% |

|

Porosity |

|

2.6% |

|

Dietmar Leeb |

HL |

>300 |

|

Three point bending strength |

Mpa |

35 |

|

Thermal expansion coefficient(25℃-1200℃) |

(10-6/K) |

-1-2.5 |

|

Thermal conductivity (At room temperature) |

W/mk |

50 |

|

Maximum operating temperature |

Air |

900℃ |

|

Vacuum |

2100℃ |

|

|

Inert atmosphere |

2300℃ |

|

|

Room temperature resistivity |

Ω.cm |

>1014 |